Agri-food robotics demand soft and effective grippers

Where the softness of grippers are useful and what else they need to achieve?

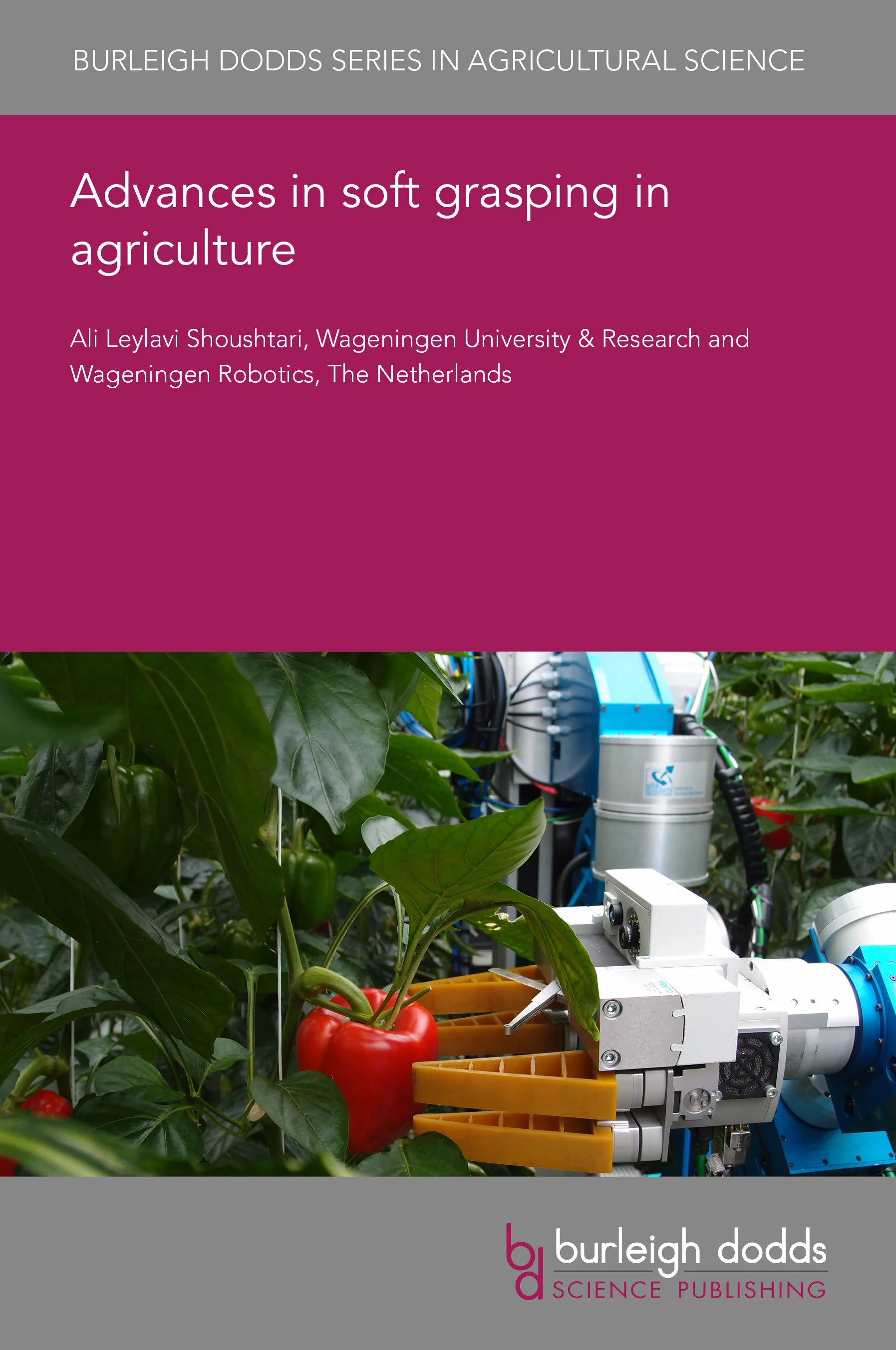

Advancing Soft Grasping in Agriculture: A New Frontier for Robotics

At Wageningen Robotics, we are dedicated to pioneering technologies that address the ever-evolving challenges of modern agriculture. Among the most promising innovations is soft robotics, a field gaining traction for its potential to transform crop handling and harvesting. This topic is the focus of Chapter 12, Advances in Soft Grasping in Agriculture, authored by Dr. Ali Leylavi Shoushtari from Wageningen University & Research, and featured in the book Advances in Agri-Food Robotics.

This chapter delves into the cutting-edge application of soft robotics in agricultural tasks, providing a structured analysis of challenges, technological advancements, and future possibilities.

The Core Challenges in Agricultural Robotics

Agricultural tasks pose unique challenges for automation:

High Diversity in Crops:

Crops vary significantly in size, shape, texture, and mechanical properties. Even within a single crop family, such as cucurbits, there can be substantial variation between cucumbers, melons, and watermelons.

This diversity is further complicated by dynamic factors such as growth stages, moisture, and environmental conditions.

Safety in Handling:

Delicate crops require safe manipulation to prevent damage. Maintaining quality during handling is essential for market viability.

Task Complexity:

Harvesting is a multifaceted task requiring not only grasping but also detaching, holding, and maneuvering in often dense vegetation.

Dense Vegetation:

Navigating through tightly packed plants requires robots to be compact and agile, avoiding collisions while completing tasks efficiently.

Traditional rigid robots fall short in addressing these challenges, but soft robotics offers a compelling alternative.

The Promise of Soft Robotics

Soft robotics introduces robots crafted from deformable materials such as elastomers, gels, and fluids, allowing for greater adaptability, safety, and precision. This technology is particularly suited for agricultural applications, where variability and fragility dominate.

Advantages of Soft Robotics in Agriculture:

Shape Adaptability: Soft robots can conform to the complex geometry of crops.

Safe Interaction: They ensure minimal damage to delicate crops, preserving quality.

Versatility: With customizable designs, soft robots can handle a wide range of tasks, from grasping and manipulating to navigating dense environments.

In agriculture, the focus of soft robotics has been primarily on gripping technologies, particularly soft grippers used for harvesting tasks. These grippers excel in handling diverse crop types safely while meeting the complex demands of agricultural automation.

Technological Developments

The chapter outlines key advances in soft grippers and provides a framework to evaluate their performance across several dimensions:

Gripper Parameters:

Strength: The ability to apply adequate force for gripping and manipulation.

Bulkiness: The gripper's compactness and maneuverability in dense vegetation.

Grasping Performance:

Safety: Preventing damage to delicate crops.

Speed: Performing tasks efficiently to ensure economic feasibility.

Object Variations:

Ability to handle differences in crop shape, size, pose, and mechanical properties.

Examples of Soft Gripping Technologies:

Electroadhesive Grippers: Lightweight and fast, ideal for handling small and fragile crops like strawberries.

Multimodal Enveloping Grippers: Adaptable to diverse shapes and capable of handling larger crops.

Hybrid Grippers: Combining soft and rigid elements to balance flexibility and strength.

Future Directions

The chapter emphasizes the need for hybrid designs that integrate multiple technologies to address the limitations of current soft grippers. For instance, combining electroadhesion for speed, multimodal designs for versatility, and tendon-driven systems for strength could result in a truly versatile agricultural gripper.

The proposed Universal Soft Robotic Harvester (USOROH) project serves as a case study of how such designs can be applied. This project focuses on intercropping systems, where diverse crops grow together, requiring highly adaptable robotic solutions.

Steps Toward the Ideal Gripper:

Developing multi-functional designs capable of addressing all challenges simultaneously.

Drawing inspiration from natural grippers, like the opposable thumb in primates, for enhanced versatility.

Leveraging open-source platforms like the Soft Robotics Toolkit for rapid prototyping and customization.

A Broader Vision for Agriculture

Soft robotics is not just about technological innovation; it’s about reshaping agriculture for a sustainable future. By addressing labor shortages, increasing operational efficiency, and supporting sustainable practices like intercropping, these technologies pave the way for more resilient farming systems.

At Wageningen Robotics, we are excited to be at the forefront of this revolution, collaborating with researchers and industry leaders to turn the potential of soft robotics into actionable solutions.

For a deeper dive into soft robotics and its applications in agriculture, check out the Advances in Agri-Food Robotics book and stay connected with us at Wageningen Robotics.

Discover More

Visit the Dutch Soft Robotics Community: dutchsoftrobotics.nl

Explore open-source tools: softroboticstoolkit.com

Description

Agricultural robotics face challenges like product variability, task complexity, and dense vegetation, requiring safer and more adaptable systems. Soft robotics, a promising field, offers potential solutions by improving handling and harvesting tasks. This chapter reviews soft grippers' success in agriculture, focusing on safety and adaptability, and provides insights for designing future soft robots.

Table of contents

1 Introduction

2 Challenges of action in agricultural robotics

3 How soft robotics can address challenges of action

4 Developing an assessment matrix for soft grippers

5 Performance analysis of current soft agri-food grippers

6 Performance analysis: dealing with object variations

7 Designing the ideal versatile gripper

8 Case study: the use of soft robotics in intercropping

9 Conclusion

10 Where to look for further information

11 References